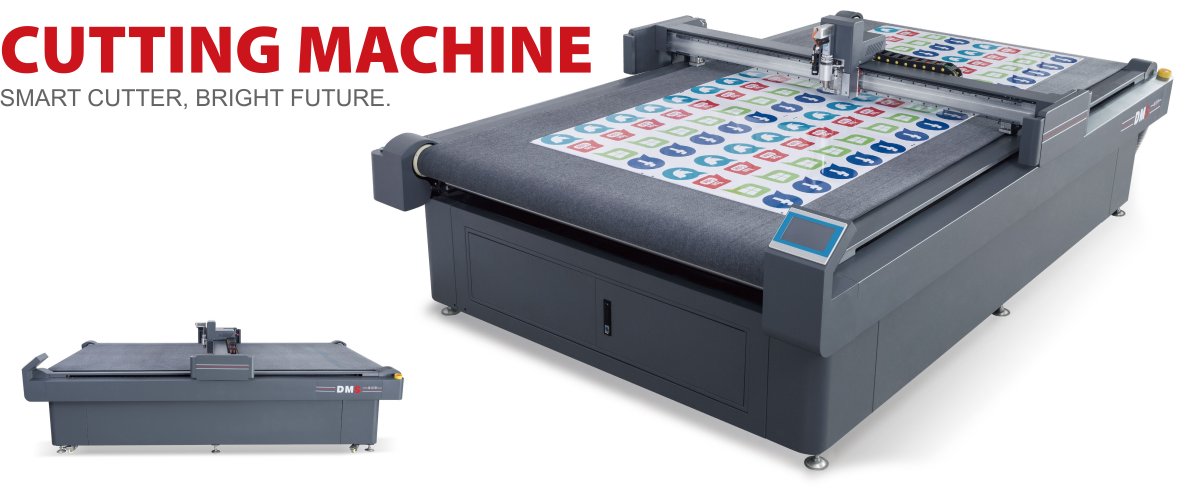

Established in 2004, DMS Electric Equipment Co., Ltd. is headquartered in Foshan, China. It is one of the non-metal cutting equipment manufacturers. It is committed to providing cutting integrated solutions for the soft materials industry. It specializes in flexible material cutting machines and profile cutting machines. ,Advertising cutting machine, manual cold laminating laminating machine, electric cold laminating laminating machine, automatic laminating machine, bottomless paper laminating machine, electric laminating machine, low temperature laminating machine, liquid laminating machine, leather glazing Machines and other equipment, hot sales in Zhejiang, Guangdong, Shandong, Hubei, Jiangsu, Shenzhen, Shanghai and other places.

The DMS R&D and production base has 40 experienced middle and senior talents, and has a large CNC machining center and assembly center. For the garment industry, automotive interior industry, advertising packaging industry, composite materials, flexible materials, composite cutting and footwear, luggage, carton boxes, leather, advertising, sofas, car seats, composite materials, electronics, etc. More than 10 non-metal industries provide solutions and services that change the customer's production model and make production intelligent. Through unremitting efforts, the company has gathered talents and institutions in strategy, marketing, marketing, research, development, operation and service, and has formed a high-performance team with rigorous attitude, fresh thinking and pragmatic.

DMS cutting machine is mainly for intelligent cutting of non-metallic flexible material profiled graphics, which can quickly complete all kinds of processes such as full cutting, half cutting, boring and milling, drilling, crease, marking, etc...

More

Head design

With a convenient and replaceable head design concept, the tool heads with different functions can be replaced and added according to actual needs.

Communication

The data interface is a Gigabit network interface, which enables remote upgrade and maintenance, and the transmission speed is fast and the distance is long.

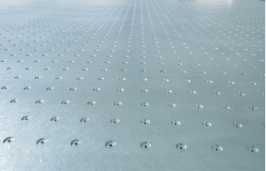

Countertop

Adopting advanced and mature rolling table design, aluminum “honeycomb” vacuum adsorption platform maintains a flat cutting platform and improves cutting precision.

Control System

Independent research and development of human-machine interface operating system, humanized design, intelligent recognition of knife cutting, fast capture of cutting targets.

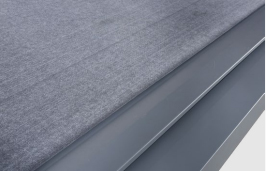

Imported felt

Imported felt, wear-resistant, breathable, ensuring high flatness of the cutting platform.

Collision avoidance

Safety anti-collision system to ensure the safety of operators.

- Company news

- Industry news

-

How to Save the Consumption of Film Coating Machine

2019-06-13

Film coating process is widely used in all kinds of packaging and decoration pri...

-

What are the common technologies of film covering machine?

2019-05-31

Coating, that is, pasting film, is to coat plastic film with adhesive, and make ...

-

How to Reduce Film Dosage in Film Covering Machine

2019-05-31

The power device of the Film-covering machine is the motor, which can be said to...

DMS Electrical and Mechanical Equipment Co.,Ltd. all rights reserved.