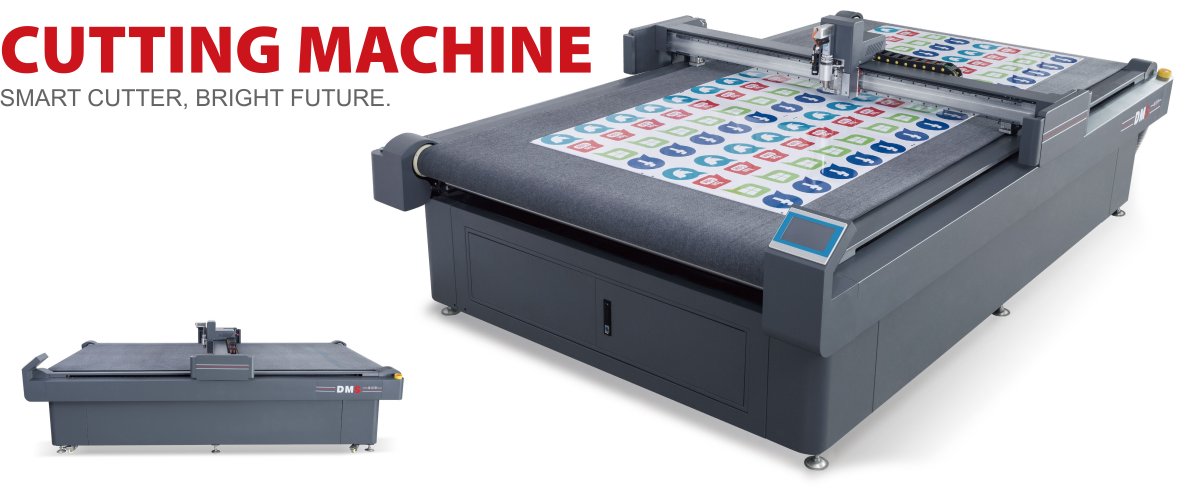

Since the advent of the DMS clothing cutting machine, from the beginning of a single cutting equipment, gradually from manual to semi-automatic to now fully automated cutting, this road has come, perseverance, continuous innovation, striving for first-class. The garment cutting machine, for the qualified finished cutting machine, also needs to run for 72 hours in the sub-working state to verify the comprehensive performance of software and electromechanical. The operation status and various data of the garment cutting machine during the testing process are recorded by the full-time inspectors of the quality assurance department in each machine filing form. Each garment cutting machine issued by DMS has established a complete quality inspection record, and the quality problem has perfect traceability, which is your first choice!

Clothing cloth cutting:

1. Subvert the traditional cutting method, CCD positioning and cutting intelligent products;

2, configuration visual and cursor manual positioning function, CCD automatic positioning function, fast and convenient cutting of clothing bags;

3. The material around the edge of the pattern can also be cut accurately to increase the utilization rate;

4, different models only need to adjust the size of the template in the computer;

5, hundreds of samples, one second shot, one second match, one second can be cut;

6. The deformation matching algorithm is added for the first time to effectively solve the cutting problem after deformation of the high elastic fabric.

Applicable materials: fur, faux fur, fake hair, artificial hair, fur, cow and sheep horse, pie to overcome, suit, home clothes, shirt, coral velvet pajamas, leather clothes, diving suits, assault suits, outdoor wear, winter clothes, Imitation wool vest, sweater, plaid shirt, woolen coat, evening dress, wedding dress, composite hair, sheep shearing, fur collar, windbreaker, quilted down jacket, space suit.

Adaptor & Application Materials

-

insole

Tool selection -

Scottish cloth

Tool selection -

Sequined flash cloth

Tool selection -

Wool

Tool selection -

Textile carpet fabric

Tool selection -

Textile fabric

Tool selection -

Cloth fabric

Tool selection -

Cloth fabric

Tool selection

Head design

With a convenient and replaceable head design concept, the tool heads with different functions can be replaced and added according to actual needs.

Communication

The data interface is a Gigabit network interface, which enables remote upgrade and maintenance, and the transmission speed is fast and the distance is long.

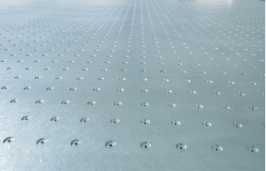

Countertop

Adopting advanced and mature rolling table design, aluminum “honeycomb” vacuum adsorption platform maintains a flat cutting platform and improves cutting precision.

Control System

Independent research and development of human-machine interface operating system, humanized design, intelligent recognition of knife cutting, fast capture of cutting targets.

Imported felt

Imported felt, wear-resistant, breathable, ensuring high flatness of the cutting platform.

Collision avoidance

Safety anti-collision system to ensure the safety of operators.

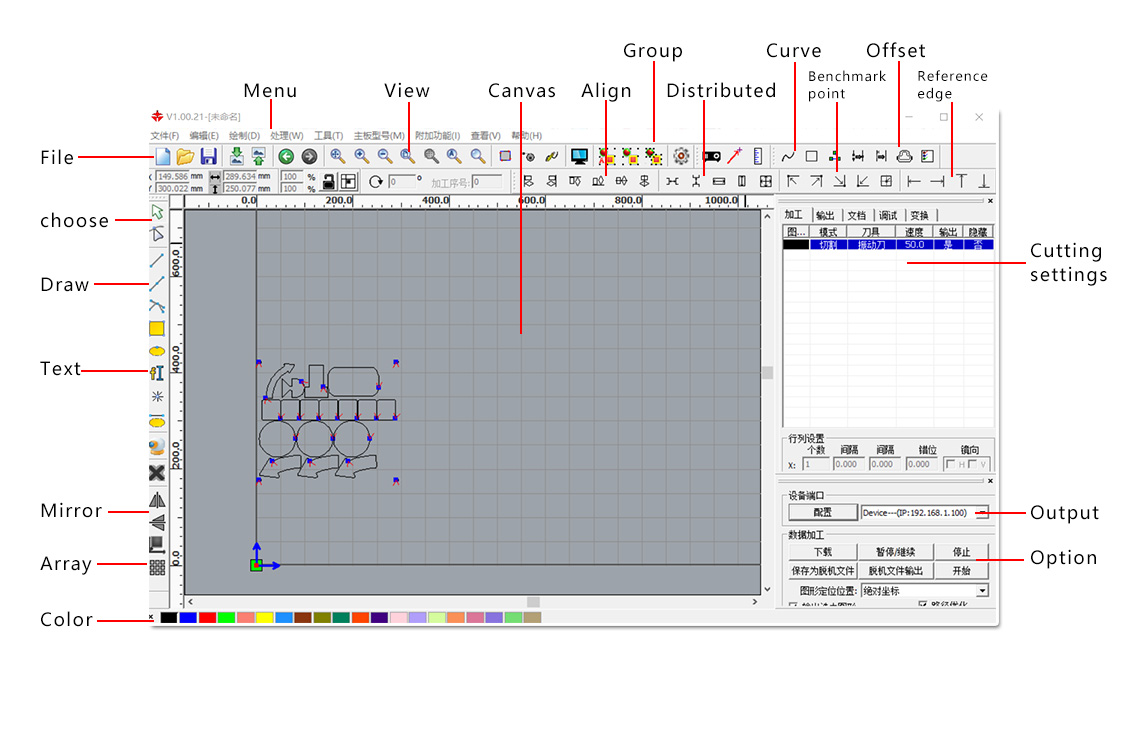

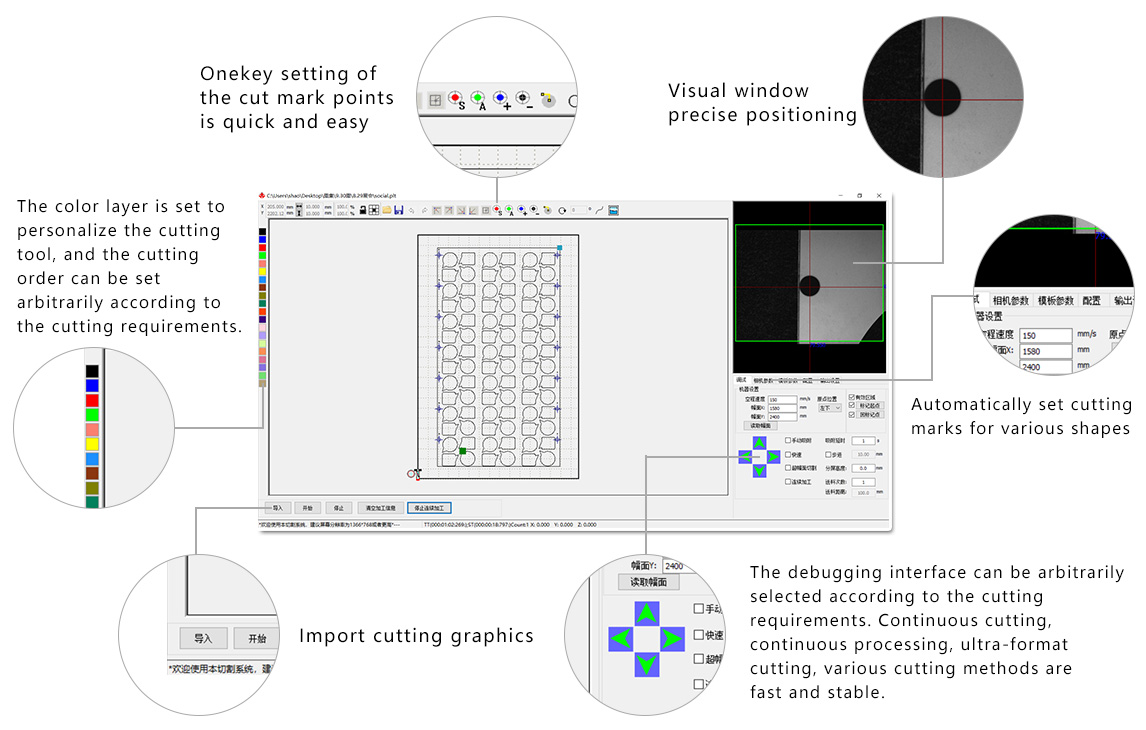

Digital cutting machine software features

DMS digital cutting machine adopts self-developed CAM software, and user requirements are perfectly integrated into software design. It is a fully automatic intelligent cutting system that combines the three advantages of performance, speed and quality, which can complete full cutting, half cutting, boring and milling, and quickly. Various processes such as punching, crease, marking, etc., the operation is simple and convenient, the function is rich and practical, and the tool quick change module can meet the customization requirements of the user.

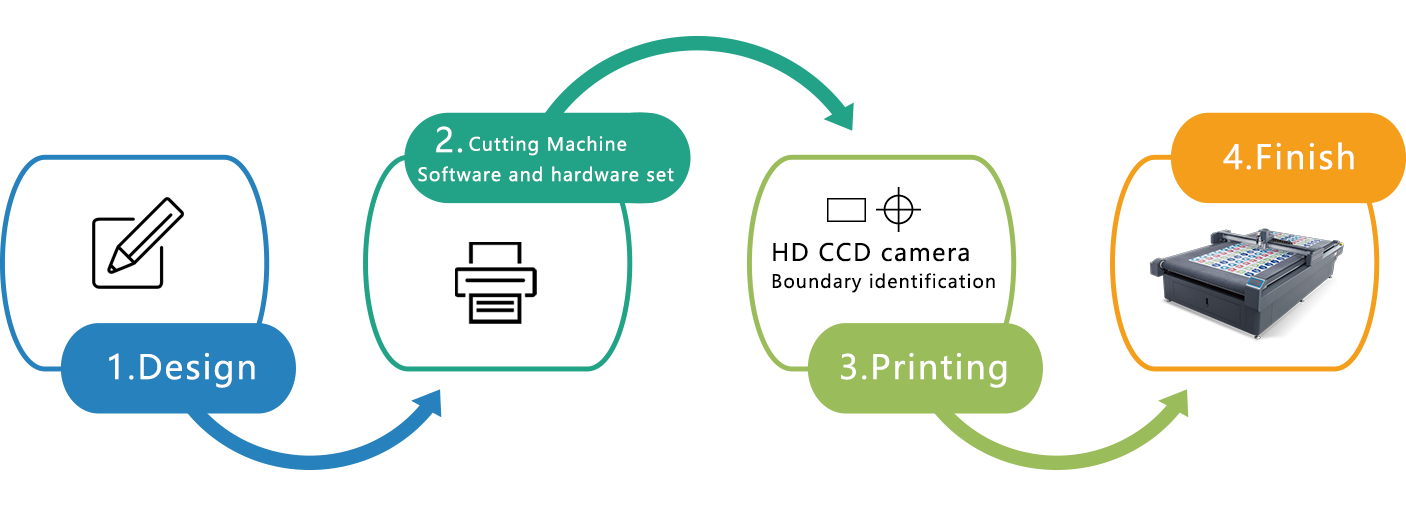

Schematic diagram of the cutting process

Clothing cutting machine cutting Technical Parameters

Main technical parameters of the equipment

| Technical parameters / model | DMS-2516A |

| Multi-function | Tools can be easily changed, with ornamental engraving, milling, vibration cutting, half cutting and creasing, drawing, the cursor position and optional precise camera position |

| Safety device | Using infrared sensors, respondive, safe |

| Moving speed | 800-1500mm/s |

| Cutting speed | 200-1200mm/s(according to different cutting materials) |

| Cutting thickness | 40mm(More than 40mm can be customized |

| Material Fixed | Vaccum System |

| Cutting tolerance | ±0.05mm |

| Servo resolution | ±0.01mm |

| Transmission interface | Ethernet |

| Network transmission distance | ≤350 m |

| Buffer capacity | 2GB |

| Transmission system | Import (Digital servo motor、Linear guide、Synchronous belt、Screw、Gear) |

| Normal power | 7.5-11KW |

| Voltage | 380V± 10% |

| Working Range | 2500×1600mm |

| Max feeding width | 1600mm |

| Product size | 3521×2186×1280mm |

| Packing Size | 3670×2340×1500mm |

| Gross Weight | 1150KGS |

DMS Electrical and Mechanical Equipment Co.,Ltd. all rights reserved.